Business

Today’s IT

and tomorrow’s future.

We support the evolution

of technology.

In 1972, Furukawa Denshi was early to take note of the properties of gallium arsenide semiconductors that promised a new generation of semiconductors, and succeeded in mass production of the high-purity metallic arsenic used in their manufacture. Since then, through the production of materials and components, Furukawa Denshi has supported the semiconductor, laser, and other technologies indispensable to the evolution of IT.

Going beyond high-purity materials, our product fields extend to aluminum nitride ceramics, optical components, cores, coils, and more. These find use in diverse electronic products, including power semiconductors and the latest IoT technologies and facial recognition technologies.

Today and tomorrow as well.

Through our ongoing support for the world’s newest technologies, we will contribute to the creation of a prosperous and comfortable society.

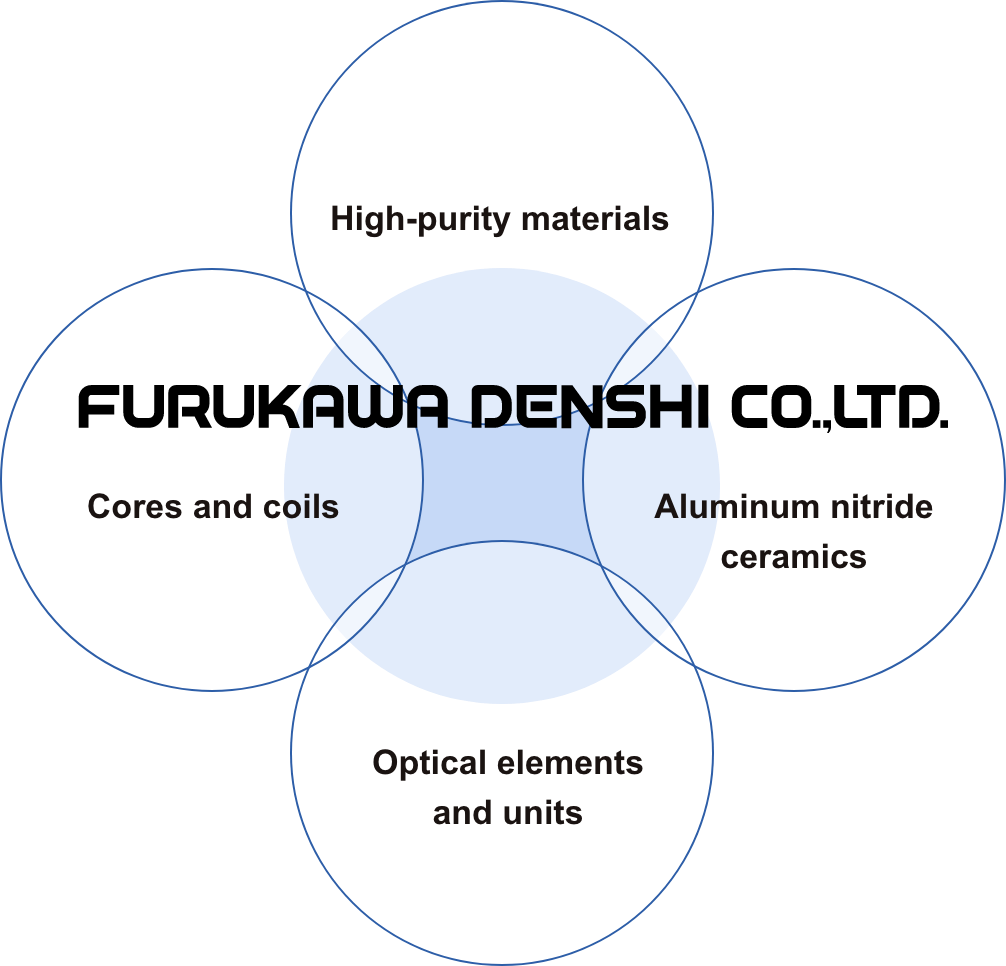

Furukawa Denshi’sfour product groups

Our products come under four groups: high-purity materials, cores and coils, aluminum nitride ceramics, and optical elements and units. The materials and elements that we develop and manufacture are indispensable to semiconductors, automobiles, and electronic products.

High-purity materials

A top manufacturer of high-purity metallic arsenic

High-purity metals and high-purity compounds support the evolution of communication technology

Furukawa Denshi was the first in Japan to succeed in mass-producing high-purity metallic arsenic for use in gallium arsenide semiconductors, which feature properties not found in silicon semiconductors. Since then, we have met most of Japan’s demand for metallic arsenic as the only domestic manufacturer of the material, offering purity as high as 99.999995% (7N5). We also boast the global top share of the material.

High-purity metallic arsenic

Gallium arsenide semiconductors, which feature high luminous efficacy and the ability to operate at high frequencies, have found use in red LEDs and lasers, satellite communication equipment, smartphones and tablet devices, key components of high-speed wireless LAN equipment, and other applications. High-purity metallic arsenic is indispensable to the production of gallium arsenide semiconductors.

In recent years, applications for the material have expanded widely to diverse electronic products, including infrared radar for autonomous driving, facial recognition systems, and blood oxygen meters.

High-purity metallic arsenic

High-purity metallic arsenicGallium phosphorous polycrystals and high-purity compounds

We manufacture gallium phosphorous polycrystals used to manufacture light-emitting diodes (LEDs) and varied high-purity compounds used for doping semiconductors with elements. From raw materials including arsenic, phosphorus, sulfur, and selenium, we use controlled pressure to synthesize compounds that require high pressure and are extremely difficult to synthesize.

Gallium phosphorous polycrystals

Gallium phosphorous polycrystals High-purity compounds

High-purity compoundsCores and coils

Reducing noise and storing and converting electrical energy

We contribute to greater stability and efficiency in power supplies and circuits

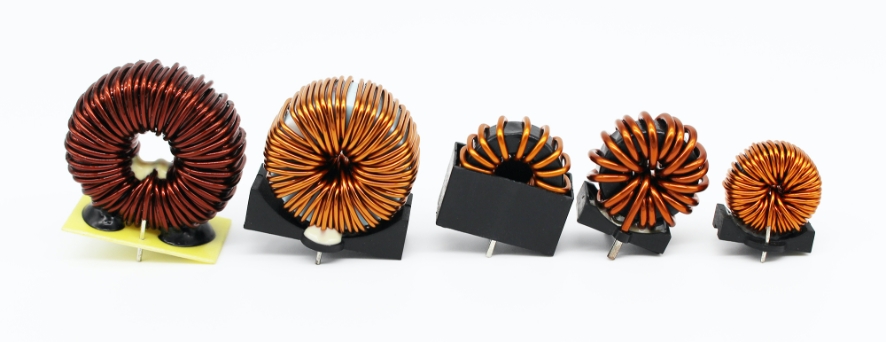

Automotive coils have become indispensable to increasingly computerized and electrified automobiles, including PHVs, EVs, and fuel cell vehicles. High reliability is demanded as well. For automotive use, industrial machinery power supplies, and other coil applications, we offer detailed solutions that match core material, sizes, forms, coil electrical characteristics, and other properties to the application from the design stage onward.

Using outstanding high-pressure press molding technology, Furukawa Denshi succeeded in forming sendust, amorphous dust, and other hard powders, and became the first company in the world to create amorphous dust coil products. Leveraging technologies and quality built up over many years of addressing automotive applications, we are able to manufacture a wide range of cores and coils from various types of magnetic materials.

The functioning demanded of coils differs according to customers’ applications. By carrying out development together with customers from the design stage onward to determine what materials are appropriate for what uses, we are able to offer optimum cores and coils and contribute to greater stability and efficiency in power supplies and circuits.

Toroidal coil

Toroidal coil Large current reactor

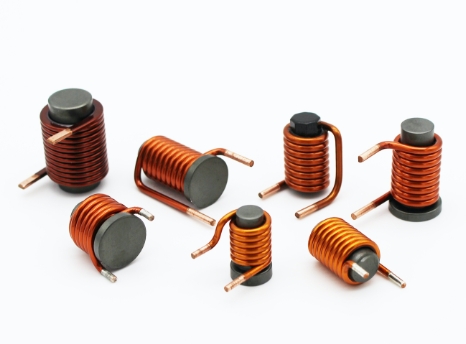

Large current reactor Axial coil

Axial coilAluminium nitride (AIN) ceramics

Ceramics that combine outstanding thermal conductivity

with electrical insulating properties

We meet customers’ requests with a variety of forms,

from fillers a few microns in diameter to parts a few hundred mm in size

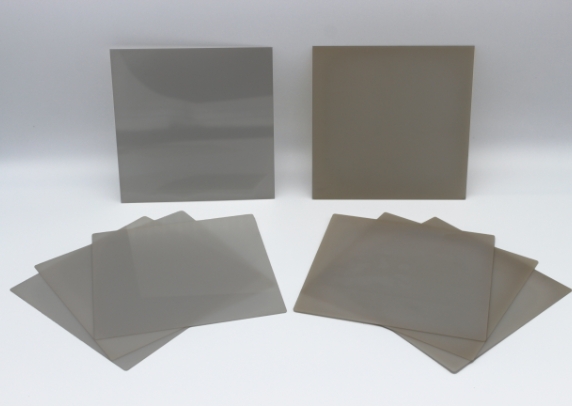

Aluminum nitride has the same thermal conductivity as metallic aluminum, but is not an electrical conductor. We develop material and parts for semiconductor manufacturing compornets, substrates, and fillers that take advantage of these characteristics.

Material and parts

Aluminum nitride ceramics readily release heat and are resistant to thermal shock. With excellent plasma resistance and a coefficient of thermal expansion close to that of silicon, aluminum nitride ceramics are used for parts that receive silicon wafers and contribute to reducing component replacement frequency.

Furukawa Denshi’s sintering technology is capable of manufacturing the world’s largest classes of aluminum nitride ceramics components, allowing us to support larger wafer diameters.

Semiconductor device components

Semiconductor device componentsSubstrate

Aluminum nitride ceramic substrates achieve both high heat radiation and electrical insulating properties. They are used as heat radiation substrates for 5G-era power semiconductors and optical communication lasers, radiating heat while insulating.

Substrate

SubstrateFillers

With outstanding filling properties in resin and ability to significantly increase thermal conductivity, filler consisting of aluminum nitride sintered into spherical form is used in heat radiation sheets and other applications. Aluminum nitride fillers contribute to improved heat radiation, a key issue as electronic components become increasingly downsized and integrated.

Fillers

FillersOptical elements and units

From laser optical components and processing heads

to diffractive optical elements

We design and manufacture infrared-region optical components

matched to customers’ needs

An optical element contains an infrared laser lens that functions to transmit, condense, and control infrared rays of a specific wavelength. We perform all operations, from selection of optimum materials to design, in accordance with customers’ applications and needs. We select from a wide variety of optical materials specialized in the infrared region, along with matching optical elements, processing heads, optical units, and other components.

Infrared optical elements

We select optimum materials, such as ZnSe, ZnS, Ge, and Si, for the intended transmission wavelength. We perform end-to-end production that spans polishing of materials to coating, and perform processing to order. We have accumulated extensive knowledge of appropriate processing conditions and processing methods for specific materials.

Infrared lenses

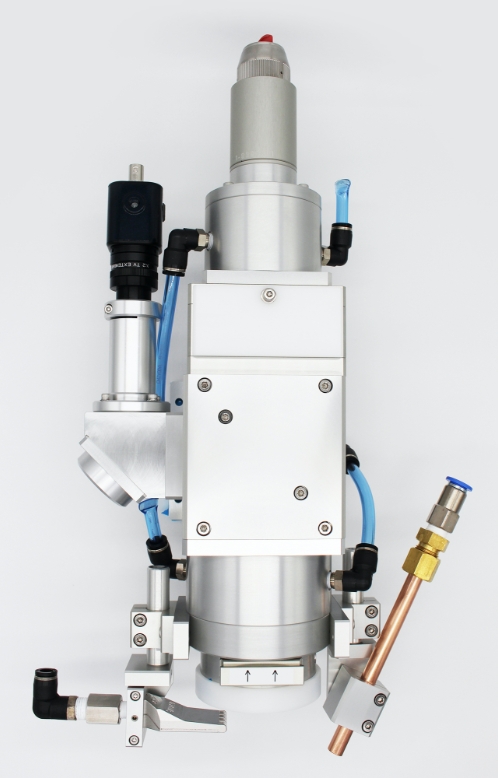

Infrared lensesHigh-power laser processing heads

and optical units

From optical design matched to laser power to casing, we manufacture processing heads in line with customers’ needs. We are also able to design and manufacture optical units such as compound lenses.

6kW Laser processing head

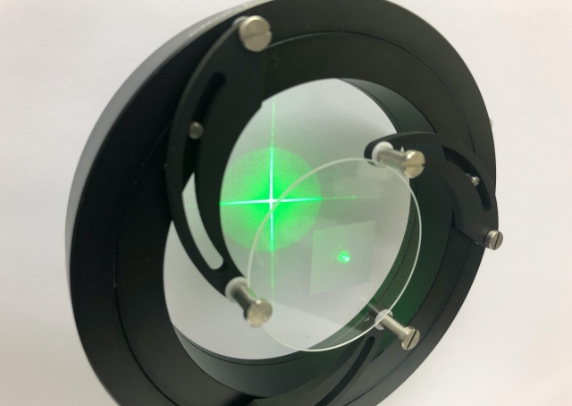

6kW Laser processing headDiffractive optical elements (DOEs)

A DOE is able to produce varied forms of light by splitting a single laser beam into multiple light beams through light diffraction. This is applicable not only to displays and sensors but also to high-power laser machining, achieving higher machining quality.

Diffractive optical elements (DOEs)

Diffractive optical elements (DOEs)